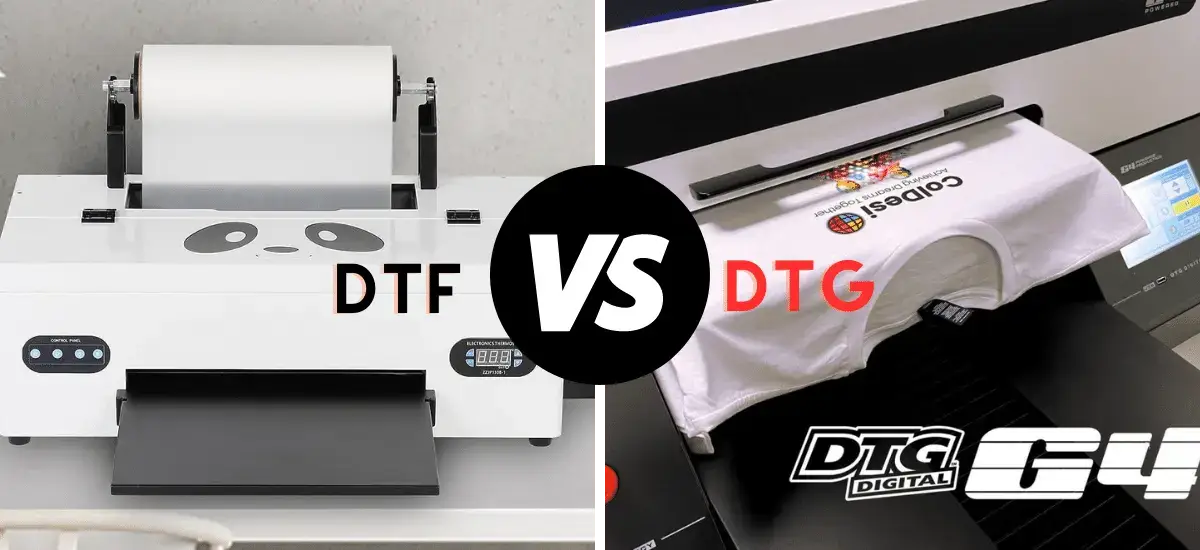

With the ongoing increase in demand for printed apparel, mugs, etc. DTF and DTG has taken the lead. Both these printing methods are equally popular, guaranteeing outstanding durability and color saturation.

In this article, we will delve into the details of these two printing methods and compare DTF and DTG printing by weighing their strengths, weaknesses, and applications. If you are a professional in the printing business or a young enthusiast making trendy apparel for your online store, this article will help you choose the best printing method.

Understanding DTF Printing

What is DTF Printing?

DTF (Direct to Film) printing is a contemporary technique that utilizes specialized adhesive film to transfer the design to your desired material. The first step is to print the design directly onto the DTF film using an eco-solvent or water-based ink printer. As soon as the film gets ready, position it on your target substrate and, by using a heat press transfer the design to it.

Advantages of DTF Printing

DTF printing has several remarkable features, making it an appealing choice for many businesses.

Versatility

An attractive feature of DTF printing is the wide range of fabrics that can be used with it. For example, polyester, cotton, blends, etc. Rigid materials such as wood and metal can also be employed with it.

Vibrant Colors

The main reason DTF prints look so eye-catching is because of their high-quality color production. The prints look vibrant and bright, making them very attractive.

Cost Effective

Are you a business holder trying to maximize your profits but also want to keep your quality standard high? Do not worry anymore, as DTF printing is perfect for you. With DTF printing, you can complete your bulk production while also breaking your pocket.

Durability

DTF printing is fade resistant so that you can satisfy your customers. They are long-lasting and can be washed multiple times.

Limitations of DTF Printing

Despite having several plus points, DTF printing has its drawbacks:

- Setting up DTF printing can be challenging for some and may require technical support.

- Intricate and detailed designs may not transfer adequately compared to other printing methods.

- When working with different materials, operators may need some assistance to achieve the best results.

Understanding DTG Printing

What is DTG Printing?

DTG (Direct to Garment) printing is a one-step process. It does not require an intermediate step, unlike DTF printing. The design can be printed directly onto the material of your choice.

Advantages of DTG Printing

Being a one-step easy method, DTG printing boasts many advantages; let’s look at them:

Ease of Use

DTG is the easiest method among all the printing techniques. It is easy to learn and can be operated easily. You can use it easily whether you are a professional or a newcomer in this industry.

No Minimum Orders

DTG printing can be perfect for print-on-demand, offering single-piece or small-batch productions. This is very cost-effective and helps to keep your budget in check.

Fine Detailing

Want your designs to stand out? DTG is perfect for you. It can beautifully and efficiently produce intricate and complex designs, satisfying your customers.

Eco friendly

DTG reduces environmental impact by utilizing water-based ink.

Limitations of DTG Printing

Despite being an outstanding printing method, it has some disadvantages which should be considered:

- DTG is comparatively slower than DTF printing which may affect time management when producing large batches.

- DTG does not work well on dark-colored fabrics, which may compromise color accuracy.

- The per-unit cost of DTG printing may be less competitive for large-scale production than for other methods.

Which Printing Method to Choose?

When deciding between DTG and DTF printing methods, you can consider the following factors:

Volume of Production

If you are looking for a more cost-effective method, then DTF is your best choice. It offers quick bulk production in record time without breaking your pocket.

Eco-friendly Considerations

Concerned about your environment and looking for a sustainable method? DTG printing employs water-based inks which align with eco-friendly practices

Material Flexibility

If you plan on working on a wide range of materials beyond garments, then DTF printing is exceptionally versatile.

Conclusion: DTF vs DTG Printing

DTF and DTG both have their strengths and weaknesses. DTF is excellent in versatility and cost-effectiveness for high-volume production, while DTG excels in handling intricate designs and on-demand printing. Your choice depends on your requirements and the niche you work in.

This article has helped you clear your doubts about the two printing methods to make an informed decision. Other factors which should be considered are budget, design complexity, desired output, and the type of substrates you plan to work on. Investing in the right printing technology may significantly impact your results and customer satisfaction.